13CBM High Frequency Heating Lumber Kiln for Drying Wood HFVD120-SA

High Frequency Heating Lumber Kiln For Drying Wood are many times faster than traditional kiln dryers. The drying process can range from several hours for thiner, softer woods to several days for thicker, harder woods.

HFVD120-SA features an automatic feeder with a quick, automated drying cycle. It has a 50KW high frequency generator, 6 T hydraulic pressure and 13 m3 capacity. It is an ideal dryer for thick hard wood typically used in the furniture and flooring industry.

All models include high-tech Programmable Logic Controllers. The PLC comes with common hardwood presets ready for use. The PLC automates the drying process by starting the hydraulic pump, HF generator, vacuum pump and water system.

The water control system pulls the moisture to an external water tank which can then be drained. The weight system calculates change data to read the moisture content of the wood.

Our engineers can provide overseas installtion, training and are available to provide after-sell service and

High Frequency Heating Lumber Kiln For Drying Wood are many times faster than traditional kiln dryers. The drying process can range from several hours for thiner, softer woods to several days for thicker, harder woods.

HFVD120-SA features an automatic feeder with a quick, automated drying cycle. It has a 50KW high frequency generator, 6 T hydraulic pressure and 13 m3 capacity. It is an ideal dryer for thick hard wood typically used in the furniture and flooring industry.

All models include high-tech Programmable Logic Controllers. The PLC comes with common hardwood presets ready for use. The PLC automates the drying process by starting the hydraulic pump, HF generator, vacuum pump and water system.

The water control system pulls the moisture to an external water tank which can then be drained. The weight system calculates change data to read the moisture content of the wood.

Our engineers can provide overseas installtion, training and are available to provide after-sell service and maintenance. We recommend proper training for sfe and prolonged use of the machinery.

Feature

*Fast drying cycle

*Automatic feeder

*Large capacity

*PLC automated systems with touch screen panel

*Uniform heating

*No sparking or bending problem

*Veneer, panels, softwood and hardwood planks, heavy timber with large dimension

*Patented weighing system, stainless steel cooling system

*Schneider, Omron, Siemens etc European spare parts

Basic Parameter of HFVD120-SA

| Overall Size | High frequency generator | 1250*1200*2050mm |

| Tank | 9000*2260*2300mm | |

| Cooling system | 1500*1150*2000mm | |

| Gross Weight | 11 Ton | |

| Tank | Inside diameter | 1900mm |

| Stacking timber size | 1300*1300*8000mm (4.26feet * 4.26 feet * 26.24 feet) | |

| Stacking timber capacity | 13 cubic meters | |

| HF Generator | Input power | 70 Kva |

| Output power | 50 KW | |

| Temperature Testing | Fiber optical temperature sensor | |

| Moisture Testing | Weighing system (PATENT) | |

| Cooling System | Stainless steel condenser with stainless steel water-ring vacuum pump | |

| Dewatering | Full automatic type | |

| Hydraulic Cyliners | 6 ton (4 pieces of stainless steel cylinders) | |

| Vacuum Pump | Material | Stainless steel |

| Power | 11 Kw | |

| Feeder Type | Automatic Feeder | |

| Tank Door | Ears Door (more safe and powerful) | |

| Weighing System | Weighing sensors under then tank (weighting wood everytime) | |

| Control System | Full-auto PLC touch screen | |

| Packing | 40" HQ (5 packages) | |

Optional Models

| Model | HF Input Power | HF Output Power | Stacking Timber Size | Stacking Timber Capacity | Container |

| HFVD30-SA | 40 kva | 30 kw | 1*1*3 m | 3 m3 | 20" |

| HFVD45-SA | 40 kva | 30 kw | 1*1*4.5 m | 4.5 m3 | 40" |

| HFVD60-SA | 70 kva | 50 kw | 1*1*6 m | 6 m3 | 40" |

| HFVD80-SA | 70 kva | 50 kw | 1*1*8 m | 8 m3 | 40" |

| HFVD100-SA | 70 kva | 50 kw | 1.3*1.3*6 m | 10 m3 | 40" |

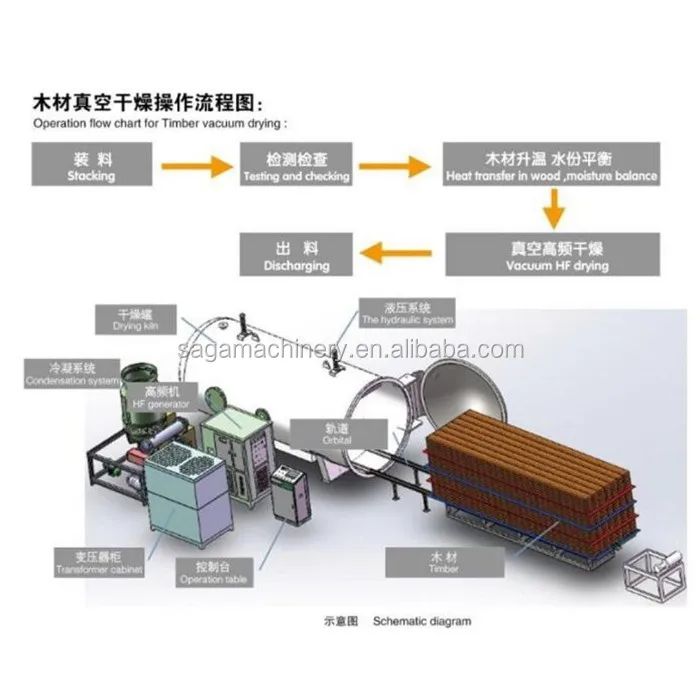

Main Parts of Saga High Frequency Heating Lumber Kiln For Drying Wood

1.High frequency generator

2.Control cabinet

3.Vacuum tank

4.Hydraulic system

5.Weighing system

6.Temperature tesing system

7.Cooling system

8.Full-auto feeder

Drying Cases

| Case | Drying Time | Drying Result | Consumption |

| Sliced veneer | about 40 hours | High quality on flatness and water content uniform | 200~250kw/cbm |

| Surface of floorboard | about 45 hours | High quality on flatness, no end cracking and deformation, no color change | about 200kw/cbm |

| Middle hardwood for second time drying | about 35 hours | Relieving tension, make water content uniform and make wood stable | about 150kw/cbm |

| Hardwood drying |

Rosewood: 7 days Red Sandalwood: 14 days |

No cracking or deformation, moisture content uniform, more stable | about 500~600kw/cbm,different consumption for different wood |

| Large plank | 7~10 days , moisture content from 60% to 20%,10cm thick+, like Birch,Larch,Pinus and Pine | No deformation on vertical direction, no cracking problem, more stable | different wood with different power consumption |

*Your email address will not be published. Required fields are marked.