Other Minerals & Metallurgy

Description

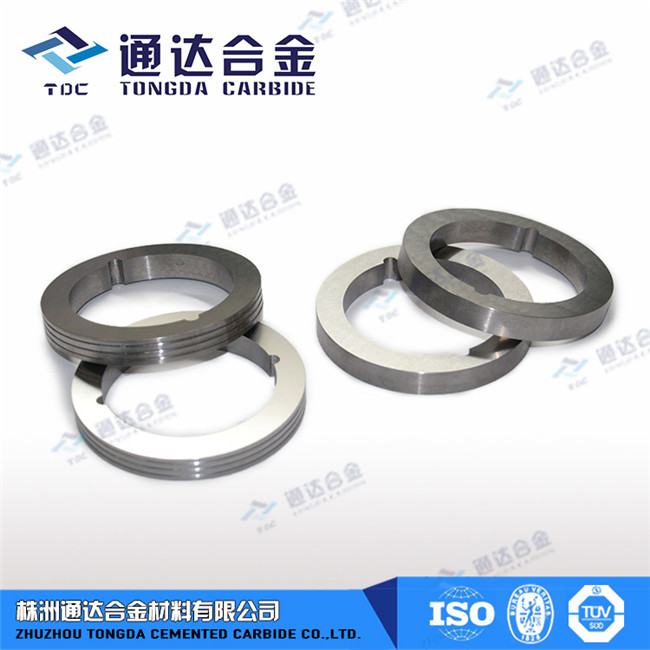

Tungsten carbide seal rings play important roles in the market of mechanical sealing industries, and they are widely used as sealing parts applying to petrochemical industries and other industries which call for superior performance in sealing.

tungsten carbide seal rings As we all know that, tungsten carbide is the additional wear resistance that can be achieved in both moving and static parts, which means that tungsten carbide seal rings have the characters of high wear resistance, high corrosion resistance and well compressive properties even under the service conditions of high temperature, and high levels of corrosion and abrasion.

Due to excellent performance of the material, tungsten carbide seal rings are used as mechanical seal faces in pumps and compressors. According to the different binders, there are several grades of tungsten carbide material, such as YG series and YN series, etc. Generally speaking, YG series tungsten carbide provides higher hardness and better abrasion resistance, while YN series tungsten carbide enhances corrosion resistance better than the former one. According to our experience, the material of 6% nickel bonded tungsten carbide and 6% cobalt bonded tungsten carbide are the most common material for tungsten carbide seal rings.

Read More

Zhuzhou Tongda Cemented Carbide Co., Ltd

carbide roller,carbide inserts,carbide drills,carbide burrs,carbide end mills,carbide saw blades,carbide ball mill jar,carbide seal rings,carbide balls,carbide nozzles

Address: Xintangpo, Hongqi Road,

Zhuzhou, Hunan

China, 412000

Tel: +8673128167654

Fax: +8673128167654