Hardware & Tools

Description

If your cycle times will be that fast, you need an electric screw drive. Then the screw can recover during cooling, mold open, eject, and close without robbing the hydraulic circuit of oil for the other machine functions.

As a side note, I have ran Engel machines with these accumalators as well. And as small as 125t, 20 mm ? screw, and capable of 500 mm/s fill rate. The press was originally built for making cell phone covers-high speed thin wall molding.

My injection mold company used electric screw drives on all machines 600t and above. The reduction in cycle times made it well worth the added expense.

Do you have balance adjustment rings in the plastic injection mold after optimizing process. Balance rings allow you to make adjustments at the tip of the blade after a dynamic check of parts.They need to be designed into the plastic injection mold.. Use MOLD FLOW to ideally balance flow from gates and gate sizes.

I think one thing to consider as well, Is the outside reps, trading companies add to the price. Injection mold tooling shops from the NA were pushed to quote Asia but that did not lower their overhead in fact it increased it by sitting idle. Which added cost plus the assumption of handling the project, travel. The savings was not enough to the customer to take the risk.

Read More

Aco Mold Manufacturing

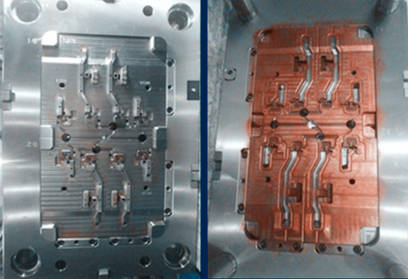

Plastic Injection Mold China

Address: No.7 fuhai fuyong,

Shenzhen, Guangdong

China, 518000

Tel: 0086-517-8689 5586

Fax: 0086-517-8689 5585